We use cookies to offer you the best experience on our site. You can find out more about the cookies we use or disable them in the settings. Cookie settings

Our services

Mecafluid stands out for its skills in 3 distinct, but increasingly complementary trades:

- Project engineering and wholesale of equipment

- Designs, manufactures and repairs in the workshop

- Placement and renovation of installations and on-site maintenance

We exercise these 3 trades in our specific areas of specialism :

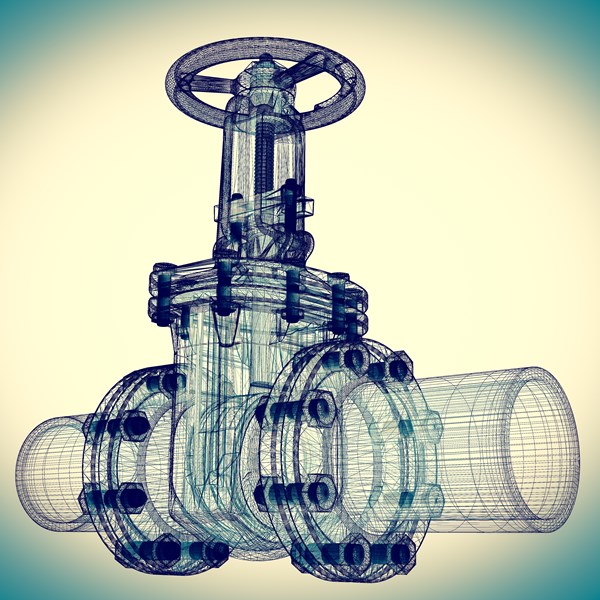

- Industrial valves (manual, pneumatic and electric)

- Pneumatic components (cylinders, air treatment...) and compressed air

- Hydraulic tooling and instrumentation

Our trades, our areas of specialism

We bring a transversal approach to the project you assign us so that we don't miss any important factors or details.

Project engineering and wholesale of equipment

Here is how we tackle your projects :

- You set out your idea

- We meet (over the phone, by email and/or in person)

- We develop your idea

- We give our utmost attention to this in order to get as much information as possible

After these different stages we can provide you with :

- A rigourous and unique design for your project

- Our personalised proposal

- Further analysis or an improvement based on your suggestions

This process obvioulsy applies for any project and any purchase, repair or replacement of a product (valve, cylinder, compressor...) or machine automation.

For the project engineering, we produce P&ID, pneumatic and/or electrical installation diagrams…

For our wholesale activity, we advise you, for example, on the valve type and material as well as its tightness and also on how it is best controlled.

We also calculate the Kv flow coefficients for you, for example.

Designs, manufactures and repairs in our workshop

This part of our business is undertaken by our technical workshop currently occupied by 5 persons.

This one is growing continuously in view of the increasing demand for the building of automated machines, pneumatic and electric actuator assemblies on valves (plus end of travel box), control boxes, regulating skids, dosing pumps, etc.

We also carry out the repair and servicing of cylinders, pneumatic and hydraulic actuators, compressors, changes of sealing parts (seals, seats) on valves, the replacement and configuration of electropneumatic positioners.

Placement and renovation of installations, and on-site maintenance

Our on-site assignments are also growing continuously. Indeed, we are frequently called upon for the partial and complete replacement or installation of compressed air networks, for compressor maintenance and the installation of pneumatic cabinets.